|

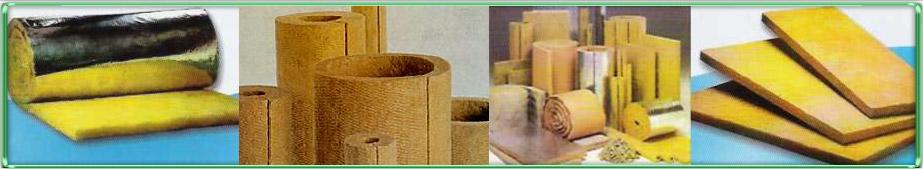

Rockloyd / Lloydrox-NODULATED ROCKWOOL

|

Rockloyd / Lloydrox-Nodulated Rockwool is a premium quality engineered mineral fibre. A specific combination of different types of volcanic rocks and well-defined bio-soluble chemicals are major ingredients for the manufactures of Lloydrox Rockloyd Nodulated Rockwool.

Lloydrox Rockloyd Nodulated Rockwool is non asbestos, organic binder free, low metallic formulation product to improve mechanical strength and structural integrity, also imparts other additional properties to the end product making it value added.

High Temperature Stability

The high thermal stability results in a stable friction co-efficient in a very broad temp range. Low thermal conduction restricts over heating and prevents other constituents from degradation.

Crack Resistance

Even dispersion of fibres with inbuilt bonding features with optional reinforcement properties reduces material wear and improves crack resistant.

Easy processing

Unique properties & easy way of processing of Lloydrox Rockloyd Nodulated Rockwool gives formulators a high degree of freedom in formulating & processing brake material.

Consistency in composition

Consistent Chemical Composition with high purity & optimal fibre length contributes for stable frictional properties in the product.

|

Less Material Wear |

|

Corrosion Resistant |

|

Noise & Vibration |

|

Frictional Stability |

|

Flexibility |

|

Melting Point 1000°C (1832°F) |

|

Specific Density 150-250 Kg/m³ |

APPLICATION

Lloydrox Rockloyd Nodulated Rockwool is used for dry as well as wet mixes for application like moulded clutch facings, industrial friction products, commercial vehicles as well as passengers car brake linings & Railways brake shoes etc

|