|

|

|

|

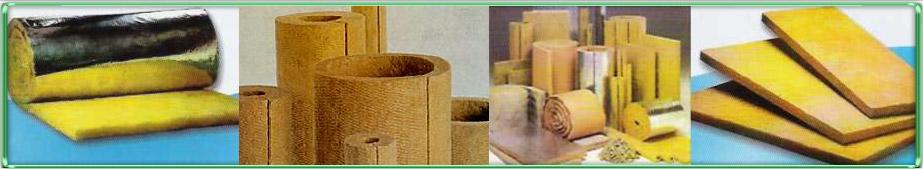

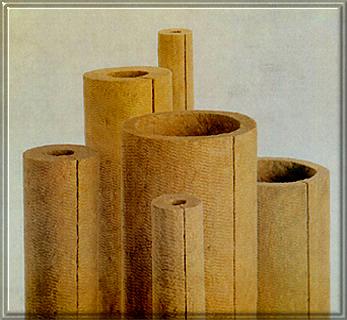

Lloydrox Rockloyd PIPE SECTIONS

|

Lloydrox Rockloyd Preformed Rockwool Pipe Section conforming ASTM - C547, IS - 9842 : 1994 and equivalent BS 3958 Part 4 is intended for the thermo-acoustic insulation and fire protection of pipe works operating at temperatures up to 750ºC. The pipe insulation is manufactured from long non-combustible rock fibers with a high performance binder.

| FIRE SAFETY |

: In Combustible |

| ACOUSTICAL PROPERTIES |

: Suitable for acoustical insulation |

| COMPATIBILITY |

: Compatible with all form of Industrial Material |

| MOISTURE |

: Water Repellent, Non Hygroscopic |

CHEMICALLY NEUTRAL, ENVIRONMENT FRIENDLY, DOES NOT SUSTAIN VERMIN GROWTH

Lloydrox Rockloyd Performed Pipe Sections are aesthetically designed for insulation of process & steam pipe lines in oil refineries, petrochemical plants, LNG plants, chemical plants, power plants and other areas where restricting heat flow plays a vital role.

Lloydrox Rockloyd Performed Pipe Sections are also capable to withstand against low and high amplitude vibrations making it more versatile in industrial applications.

TECHNICAL SPECIFICATION

| Standard Densities* |

: 144 & 150 Kg/m3 |

| Service Temperature |

: up to 750°C |

| Standard Thickness** |

: 40, 50, 65, 75 mm |

| Standard Size |

: 1 Running Metre (RMT) |

| Diameter Range |

: 12.5 mm to 350 mm nominal bore |

| Facing |

: Also supplied with AL. Foil facing on outer side |

* Other Densities are manufactured on request.

** Other thickness from 20 to 100 mm in steps of 5 mm can also be offered on request.

THERMAL CONDUCTIVITY

Lloydrox Rockloyd Performed Pipe Sections offers the LOWEST THERMAL CONDUCTIVITY TO-WEIGHT ratio, hence minimizing the total mechanical load on the applied equipment. This is certified as per ASTM C 547. Thermal Conductivity or k-value of our material does not exceed the values mentioned in the adjacent table given.

Density (Kg/m3) |

Mean temp.(°C) |

Thermal Conductivity

(mW/cm°C)

|

144-150 |

50 |

0.43 |

100 |

0.52 |

150 |

0.62 |

200 |

0.70 |

250 |

0.85 |

300 |

1.00 |

FIRE RESISTANCE

Incombustible when tested as per ASTM E-84 & IS-3144. Melting point of Fibres is above 1000°C

CORROSION PROTECTION

Lloydrox RockloydFibres are having negligible impurities like halides (chlorides and fluorides) and sulphides, which are commonly found in other insulation materials, as tested according to ASTM C795.

This is due to the fact that Lloydrox Rockloydfibres are manufactured by dry manufacturing process and its faint alkalinity actually fights corrosive reactions.

WATER REPELLENT

Lloydrox RockloydPerforms Pipe Sections, by virtue of their fiber surface treatment and lay pattern, having an angle of contact exceeding 90°, resulting in good resistance to water absorption and moisture ingress. Lloydrox RockloydPipe Sections don't promote capillary action.

COMPRESSION PROTECTION

Lloydrox RockloydFibres are having negligible impurities like halides (chlorides and fluorides) and sulphides, which are commonly found in other insulation materials, as compared according to ASTM C795. This is due to the fact that Lloydrox Rockloydperformed pipe section is manufactured by a dry manufacturing process & its faint alkalinity actually fights corrosive reactions.

SALIENT FEATURES

|

Longer life, permitting reuse after removal during maintenance. |

|

Higher thermal performance, as it is made out of rich siliceous Rockwool. |

|

Environment friendly, as there is no feathering (which normally pollutes the environment). |

|

Uncontaminated, as manufacturing is a totally dry process. |

|

Non-wicking. |

|

Good compressive strength. |

|

Excellent resistance to vibration & jolting. |

| ADVANTAGES |

|

Excellent thermal & acoustic with Fire Protection |

|

|

Non-Combustible |

|

Water repellent |

|

Excellent thermal resistance |

|

Chemically Inert |

|

Negligible Chloride Content |

|

Energy Conservation & fuel saving |

|

Ease of application |

|

Cost Effective & Maintenance Free |

|

CFC & HCFC Free |

|

|