|

|

|

|

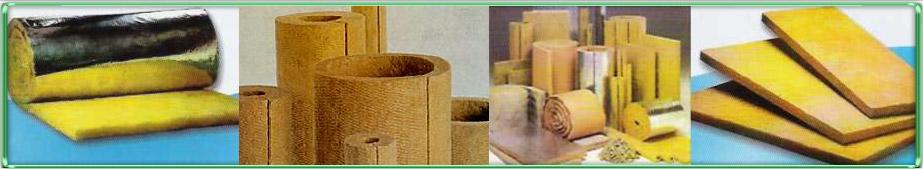

PUF / PIR SLABS & PIPE SECTIONS |

PUF materials are suitable for temperature range between -200°C to +110°C. PIR Slabs & Pipe Sections are suitable for use between -200°C to +145°C. It has low thermal conductivity value of maximum 0.021 w/mk at 10°C. It is not easily ignitable and has negligible water permeability. It is suitable for cold / chilled pipelines, building roof & wall insulation, equipment insulation and horton sphere insulation.

PIR is suitable for LNG pipe insulation.

CFC Free

PUF / PIR is the only CFC Free product, designed within the guidelines of the Montreal Protocol, 1987, for the protection of the Ozone layer.

Better Extreme temperature performance

Unlike most thermoplastics, PUF / PIR has low smoke emission and will not melt or drip in a fire,

Being rigid Polyisocyanurate foam, it also has a higher hot surface performance of 150°C compared with only 110°C of normal Polyurethane Foam. This makes it ideal for use directly over steam or electrical tracing.

Its fire classification meets even the stringent requirements of the British Board of Trade for shipboard insulation as per BS 5608, the Indian Navy, and those of the US Bureau of Mines.

Better Cost-effectiveness

With PUF / PIR, insulation thickness can be reduced by 50% compared with cork, 44 compared with expanded polystyrene or fiberglass. It exposes lower surface area, reducing area or expensive vapour barrier and outer cladding per running meter of piping.

So insulation parameters can be upgraded without increasing pipe rack spacing.

Ease of application

Resistant to almost all solvents, PUF / PIR is compatible with cold applied adhesives, sealants and vapour-barrier mastics.

PUF / PIR is available in boards, pipe sections, radiused and beveled lags, with or without factory laminated facings.

Cast-Insitu Applicationn

Material Applied at site & suitable for large dia pipelines, underground pipelines & storage tanks.

TECHNICAL SPECIFICATIONS FOR PUF / PIR BOARDS & PIPE SECTIONS

PROPERTIES |

POLYISOCYANURATE |

POLYURETHANE FOAM |

Density |

32 + 2 Kg/m³

Higher densities available. |

36 + 2 Kg/m³

Other densities available on request. |

Compression Strength

(In direction of rise) |

172 KN/m² (1.75 Kgf/cm²) |

172 KN/m² (1.75 Kgf/cm²) |

Thermal Conductivity

‘k’ (initial) at 100C |

Max 0.021 W/mk (0.15 BTU-in/hr.sft.degF) |

Max 0.021 W/mk (0.15 BTU-in/hr.sft.degF) |

Temperature Limit |

+ 1500C to - 2000C |

+ 1100C to – 1800C |

Fire Resistance Properties

Surface Spread Flame

(BS:476 Part-7, 1987)

Ignitability

(BS : 476 Part-5, 1968)

Mean Extent of Burn

(BS: 4735 Part-7, 1971) |

Class – 1

Class ‘P’ (Not Easily Ignitable)

Less than 25mm |

-----

Class ‘P’ (Not Easily Ignitable)

Less than 25mm |

Toxicity |

1.0142 |

----- |

Smoke |

780.89 |

----- |

Oxygen |

25 |

----- |

Water Vapour Transmission

(BS:4370 Part-2, 1972) |

5.84 x 10-3 μg-m/s N |

5.84 x 10-3 μg-m/s N |

Closed Cell Content |

90% (Min.) |

90% (Min.) |

Available Size |

- Boards 1m x 0.5m

- Pipe-Section to suit 50 to 250mm NB x 1m long.

- Other sizes available on request.

- Shiplap pipe-sections.

- Thickness from 25mm to 100mm & Cast-in-Situ.

|

- Boards 1m x 0.5m

- Pipe-Section to suit 50 to 250mm NB x 1m long.

- Other sizes available on request.

- Custom moulded shapes to suit Harton spheres and shiplap pipe-section.

- Thickness from 25mm to 100mm & Cast-in-Situ.

|

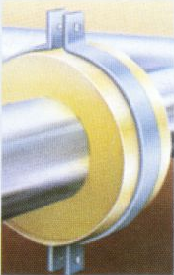

POLYURETHANE PIPE SUPPORTS

A heavy duty easy to install prefabricated pipe support system of truly revolutionary proportions. Pipe Supports are made from specially formulated chemical systems that results inn high density rigid polyurethane foam. The very nature of the material immediately yields several advantagess:

PROPERTY |

ADVANTAGES |

Wide Density Rage Possible |

Higher densities enable higher loads without increase in surface area. |

Pre-Engineered at our factory |

No sawing and shaping at site.

The support precisely matches pipe’s OD.

Installation time dramatically reduces. |

Material has a closed cell structure |

Does not permit water penetration.

No wet rot.

No dry rot. |

Excellent ‘k’ value |

Provides vastly superior insulation as compared to timber and other materials.

No condensation at support point. So no drips, puddles or energy wasted. |

Good fire resistance |

Improved safety at site.

Improved durability. |

Closed Dimensional tolerances. |

Pipe Support thickness precisely matches insulation thickness, resulting in neat finish at support location. |

Supplied in assembled condition, completed with all metal attachments. |

Improved speed of installations.

Joint-free in the load bearing area, even for larger diameters of pipe. |

Special Sizes, Shapes and Finishes |

On request On- Standard sizes & shapes can be manufactures to suit specification. Supports can be supplied with a factory – applied coat of fire-resistive mastic, which also serve as a vapour barrier, on the exposed surface, |

polyurethane products , puf panel , puf panels india , puf panels , insulation materials , insulation material , puf panel manufacturers india , puf panels india , PUF / PIR products , PIR Products , PUF Products , wall insulation , interior wall insulation , best wall insulation , wall insulation products , wall insulation panels , roofing insulation , cold insulation materials , thermal insulation materials , cold insulation , heat insulating materials , insulation materials , cold insulation material , insulation material , insulating materials , heat insulation materials , insulating material , sound insulation materials , heat insulation material , building insulation materials , roof insulation materials , sound insulation material , roof insulation , sound insulation , wall insulation , roof insulation material

|

|